Non-Destructive Inspection Lab System: LEAsys

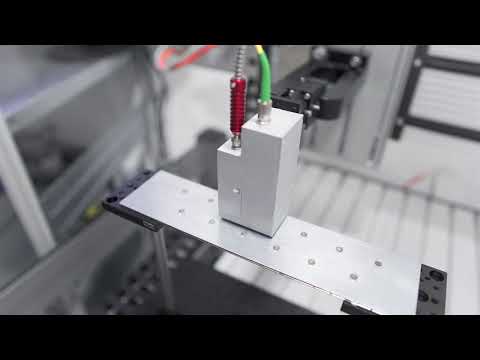

Contents:- LEAsys is XARION’s turn-key solution for contact-free nondestructive testing including scanner, data acquisition hardware and software for measurement control and data analysis

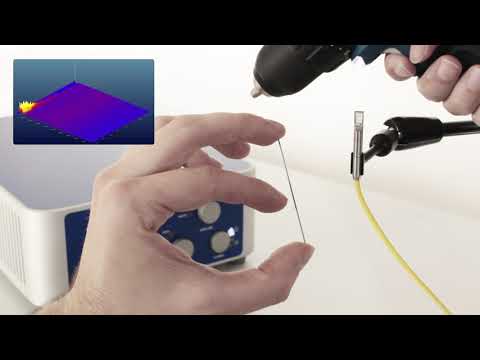

- LEAsys is based on the LEA (Laser-Excited Acoustics) technology, which combines laser excitation of ultrasound and detection with the optical microphone

- The noncontact, broadband inspection technology opens a variety of new possibilities for inspection of composites, metals and semiconductors