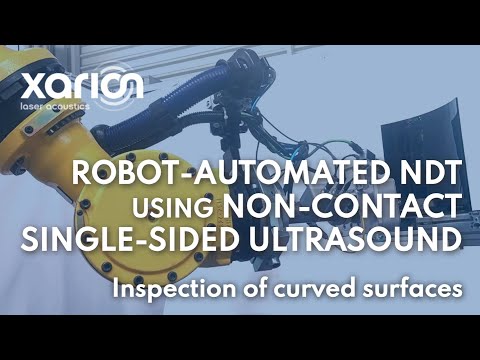

XARION's Robot-Automated NDT using Non-Contact Single-Sided Ultrasound

Contents:- Robot-automated sensor technology, enabling contactless inspection of complex-shaped parts in production environments

- Enabled by XARION's single-sided, non-contact ultrasound technology

- Allows 3D C-Scan visualization of complex, freeform surfaces