Real-time Process Monitoring

Ultrasonic Welding Monitoring

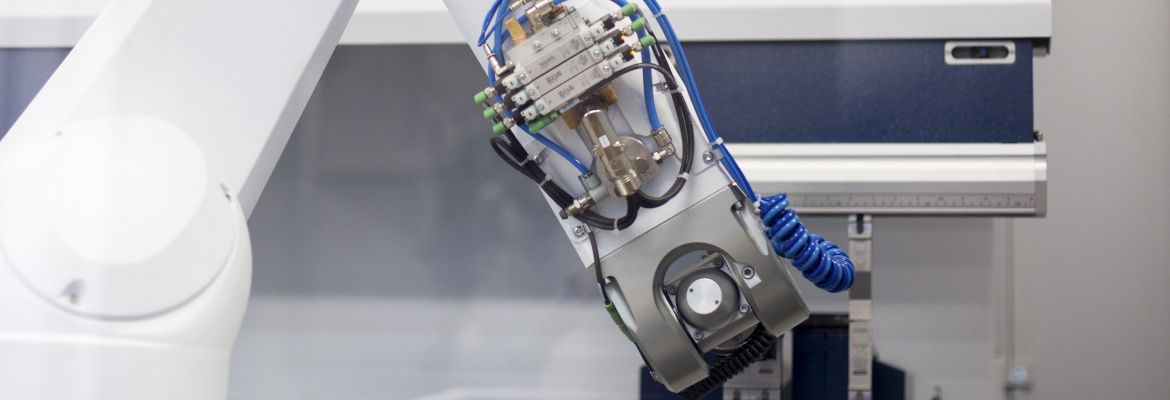

Through extensive infield studies, XARION has developed a method to extract information about a weld’s tensile strength, directly from the acoustic signature of a sonotrode-based welding process. This method allows production lines to significantly boost their quality assurance by providing accurate OK/NOK classification along with each and every weld.

(Ultra-Short Pulse) Laser Process Monitoring

Laser processes emit light — and ultrasound! The airborne ultrasound emission can be harnessed to monitor laser processes, particularly for pulsed laser processes such as laser ablating, surface structuring, or laser drilling. Also, additive manufacturing such as powder bed fusion (PBF), selective laser melting (SLM), direct energy deposition (DED), laser metal deposition (LMD) and wire-arc additive manufacturing (WAAM) can be monitored for process quality in real-time.

Crack Detection

The ultrasonic frequencies exceed the audible human hearing range 100-fold. In the ultrasound regime (free from background noise), crack signals of brittle materials, such as ceramics or high-strength alloys, can easily be picked up by the Optical Microphone as a means of in-line ultrasound process monitoring.

AI-based Machine Diagnostics

Due to the Optical Microphone's immense frequency bandwidth, every recording contains a vast amount of data available for feature extraction. We utilize classification and regression, SVM algorithms, k-means clustering and other methods to achieve unprecedented correlation between acoustic process signal and final product quality.