NDT Scanning System – LEAsys

Your tool for contact-free ultrasonic testingXARION's LEAsys turnkey ultrasound inspection system is the perfect tool for R&D laboratories or research institutions engaged in the non-destructive testing of composites, metals, and adhesive joints. The integrated NDT scanner solution combines the innovative laser-excited ultrasound technology (LEA) and the patented Optical Microphone with a high-resolution x-y scanner table and real-time data analysis software. It enables contact-free ultrasonic testing at high resolution and high speed!

The ultrasound signal is generated directly in the sample via laser beam. In addition to the standard configuration, a version with an eye-safe LIDAR laser (Class 1 system) is available, designed for use in open environments without laser safety enclosures.

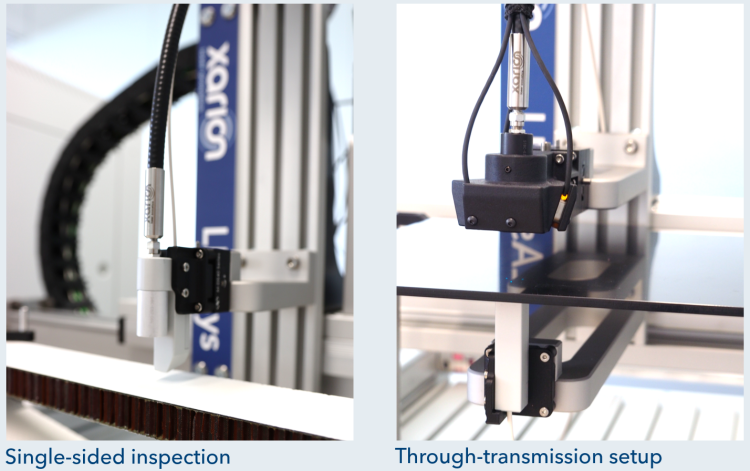

XARION's proprietary Optical Microphone detects the ultrasound signal transmitted or reflected from the sample. Single-sided (pitch-catch or pulse-echo) as well as through-transmission measurements can be performed, allowing the detection of internal defects, delamination or porosity in a contact-free manner.

For high-speed applications, XARION offers an eight-channel microphone array system with inspection speeds of up to 50 meters per hour!

Technology comparisons

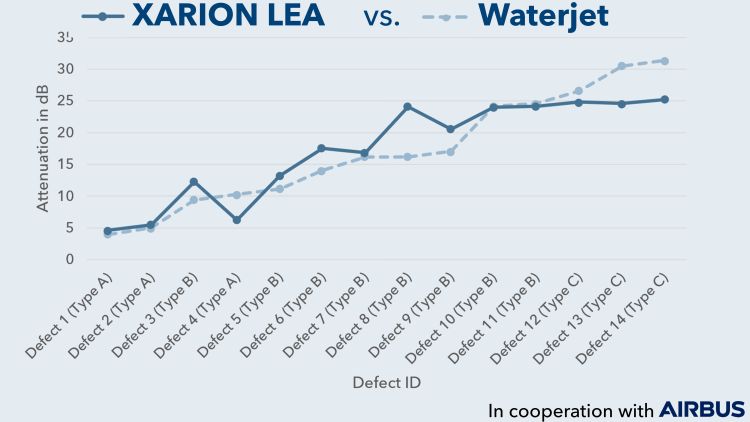

In a direct comparison with a conventional 1 MHz waterjet ultrasound system, XARION's LEA technology demonstrated its capabilities on a 20 mm Nomex® honeycomb sandwich component: Different defect types (A, B, C) were detected just as reliably — without water, gel, or physical contact. This makes laser-based ultrasonic inspection an ideal solution for modern automated inspection processes where couplants are simply not practical.

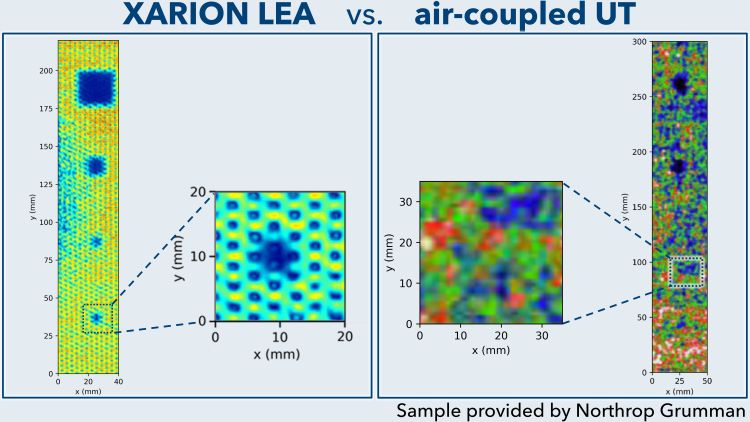

Compared to piezoelectric air-coupled systems (ACUT), XARION's LEA technology shows a clear performance advantage: Measurement speed is about five times faster, frequency bandwidth is roughly 100 times higher. At the same inspection time, the resolution is significantly higher. With this, XARION sets a new benchmark in contactless acoustic material testing.

Hardware features

- Excitation: Variable repetition rate laser up to 4 MHz

- Detection: Eta600 Ultra optical microphone with 4 MHz bandwidth

- Step size: Resolution down to 10 µm or scanning speed up to 1 m/s

- Scan area: 0.5 m x 0.5 m (LEAsys S); larger variants available

- Data acquisition: 16-bit resolution, 80 MS/s

Software features

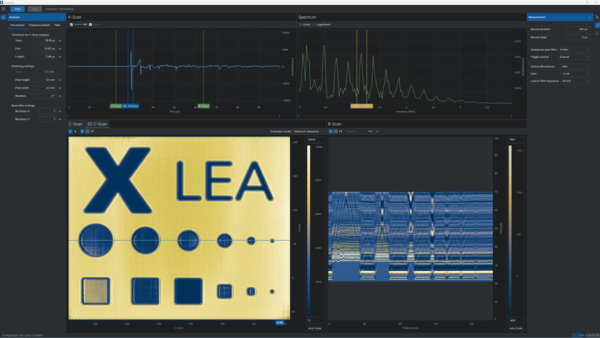

- Graphical user interface for control and data analysis

- Real-time display of A-, B-, and C-scans in 2D and 3D

- Integrated spectral analysis and F-scan visualization

- Powerful signal processing with FIR and wavelet-based filters

- Programmable API for creating automated measurement and analysis routines

- Comprehensive data export capabilities